A Guide to BACA’s Granite Cutting Machines

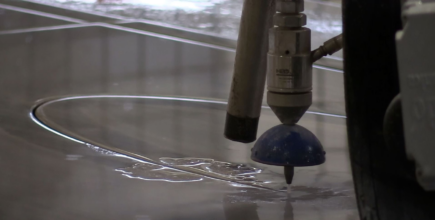

BACA Systems, CNC Stone Machining, Granite Cutting Machines, Miter X, Paladin CNC Router, Robo SawJet, Stone Fabrication Stone cutting products are used in a range of residential and commercial applications. Cutting through granite, marble, quartz, and ultra-compact materials requires precision and...Read More