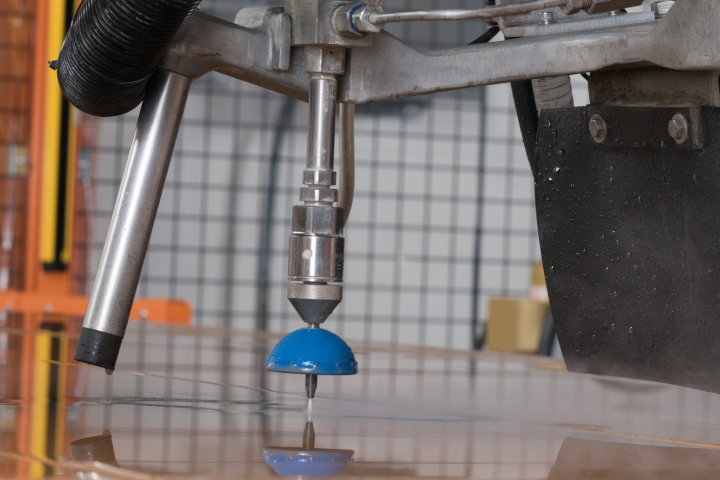

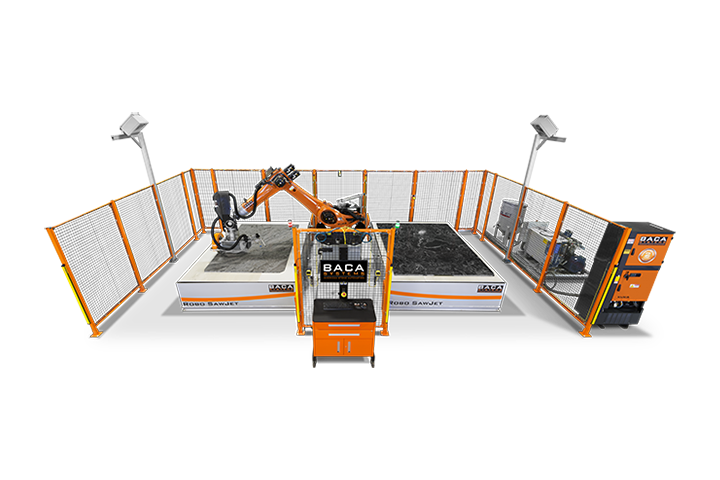

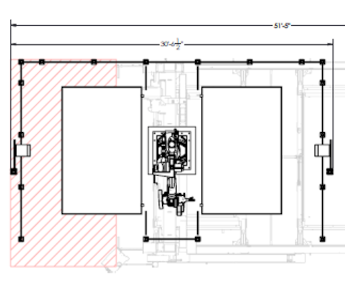

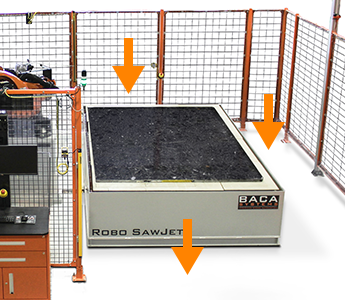

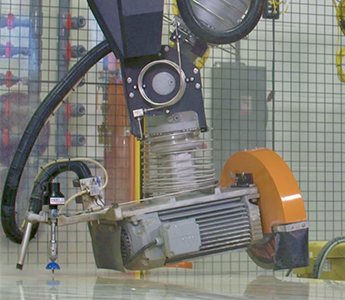

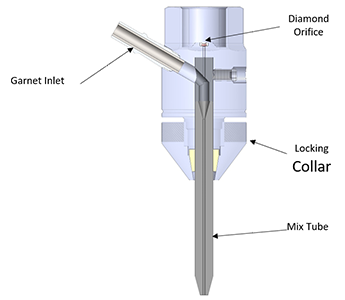

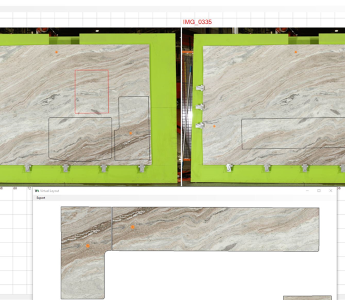

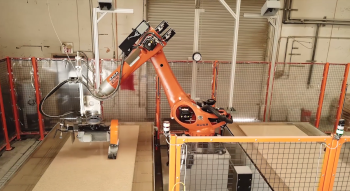

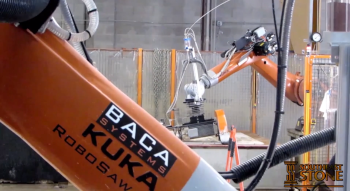

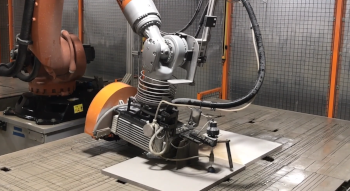

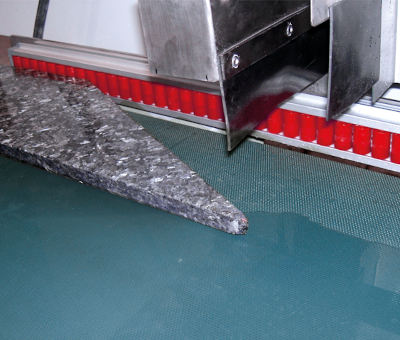

At the heart of the Robo SawJet 2.0 lies a robust foundry-grade KUKA KR 210 robot, equipped with a powerful 26HP saw motor and a 50HP H20 waterjet. Renowned for their high reliability and precision accuracy, KUKA robots are the go-to choice for the most demanding applications, including those in automotive plants and aerospace. Unlike custom-built gantry machines, robots require significantly less maintenance. Annual upkeep on the robot involves greasing (2) zerk fittings, and an oil change is recommended at either 10,000 hours of use or after 5 years, whichever comes first. Maintenance for the waterjet on the Robo SawJet is streamlined for simplicity. The waterjet lines are easily accessible on the exterior of the robot, eliminating the need to navigate through conventional cat tracks as seen with some competitors. This user-friendly design is complemented by BACA's Waterjet Made Easy exchange program.