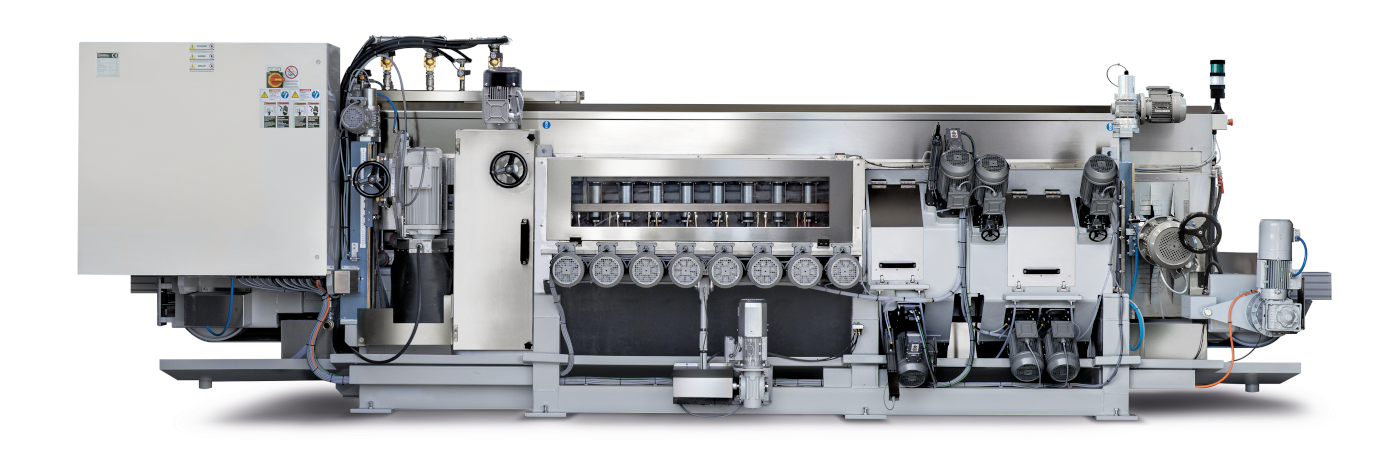

EDILPLUS

HORIZONTAL EDGE POLISHER

EDILPLUS

HORIZONTAL EDGE POLISHER

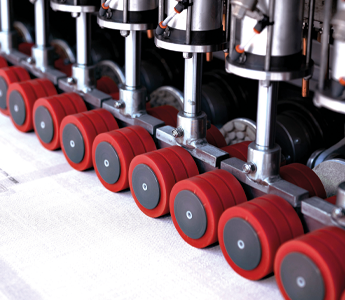

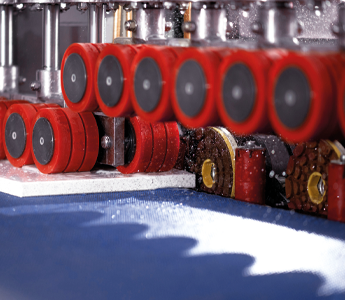

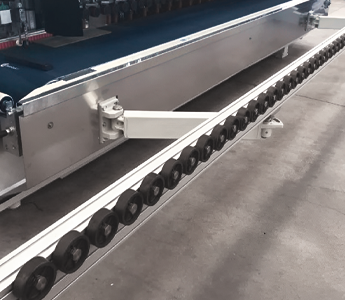

The Comandulli Edilplus is a high-productivity multi-spindle belt polishing machine engineered for marble, granite, engineered stone, and ceramic.

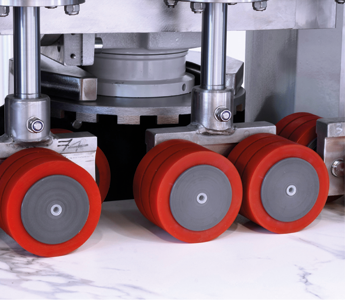

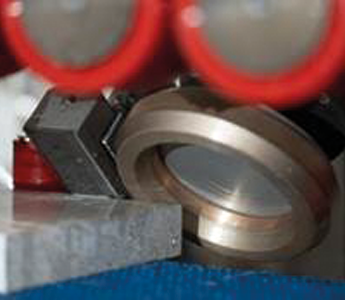

Equipped with the patented TMM Calibrator, the Edilplus delivers precise bevels and consistent polish on all material types.

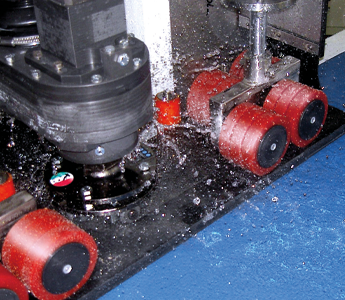

1-PASS

POLISHING

POLISHING

MULTI FUNCTION CALIBRATOR

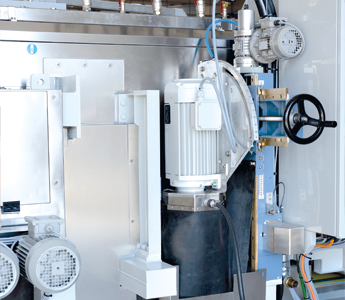

VERTICAL

SPINDLE

SPINDLE