Defender

CNC SINK ROUTER

Defender

CNC Sink ROUTER

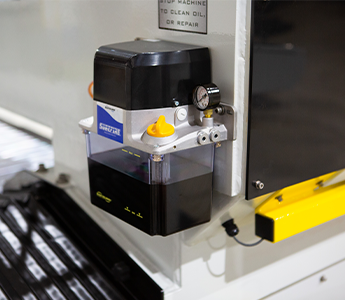

Experience seamless productivity with our cutting-edge CNC sink router can be equipped with infeed/outfeed rollers, ensuring lightning-fast load & unload times. A 21-position tool holder & a robust 20 HP American-made spindle by BBM, this machine guarantees unparalleled precision & efficiency. With Fanuc motion controls & pre-programmed sinks for effortless programming, operation becomes intuitive & hassle-free. Its superstructure monoblock design not only minimizes deflection but also facilitates easy installation, all within a compact floor plan. Precision ball screws further enhance performance by preventing gear lashing, ensuring consistently superior results with every use.

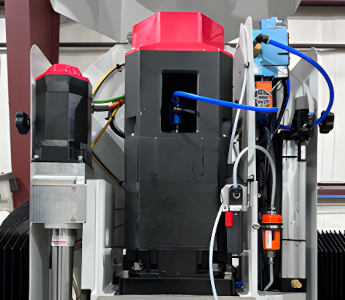

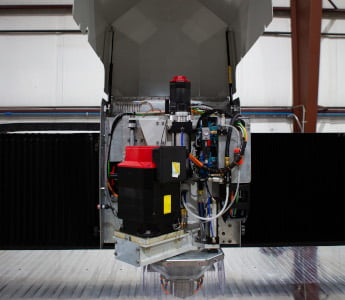

20-HP Spindle

12,000 LB MONOBLOCK

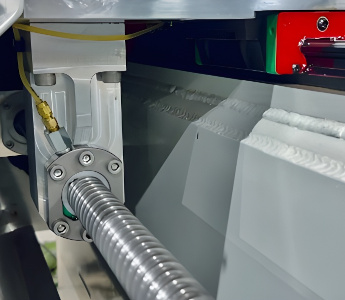

BALL SCREW