Straight 8

VERTICAL EDGE POLISHER

Straight 8

VERTICAL EDGE POLISHER

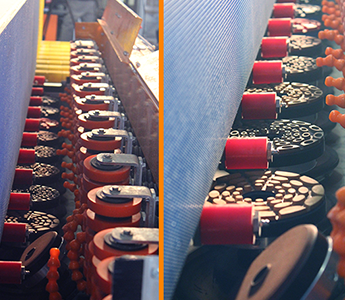

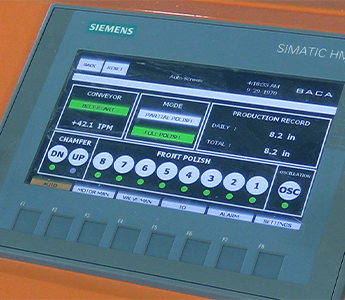

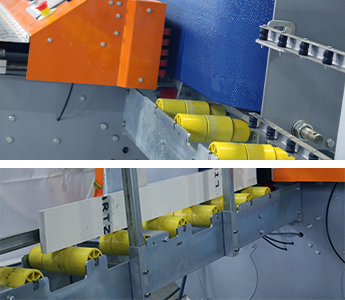

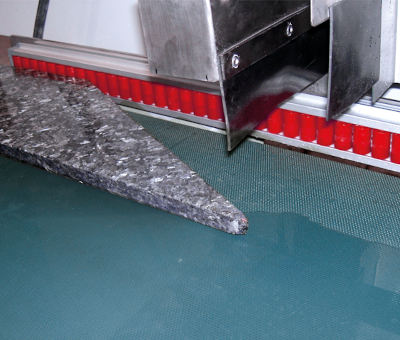

The Straight 8 was designed to edge, polish & chamfer backsplash and countertops in a single pass. The machine works on a continuous mode operation, meaning that all pieces are loaded one after the other, while moving past 8 polishing motors that result in a finished product which includes a top and bottom micro-bevel when needed. The 8 polishing motors is where the name Straight 8 originated from!

1-PASS

POLISHING

POLISHING

8+2 POLISHING

POSITIONS

POSITIONS

EASY 2 USE