Introducing

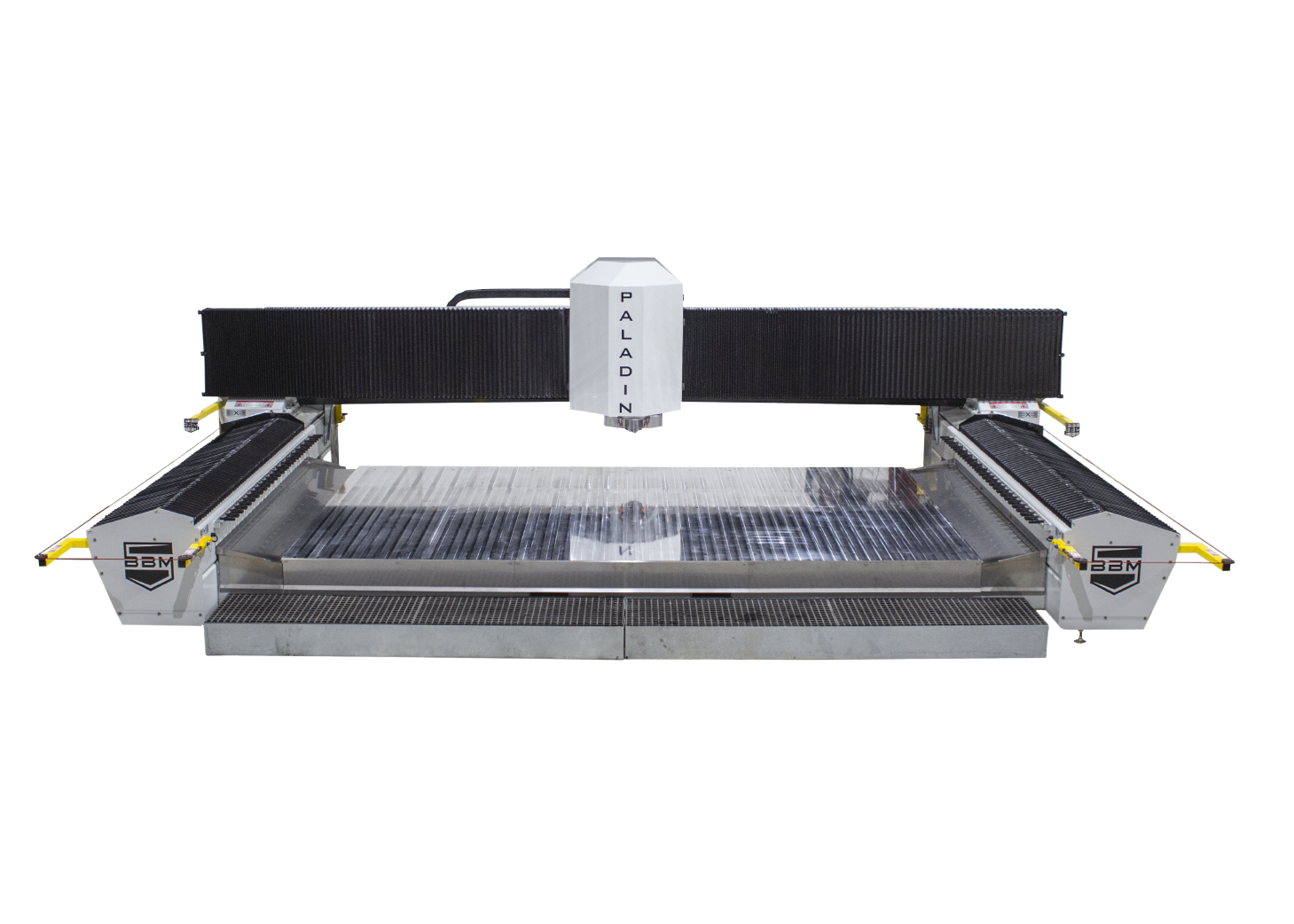

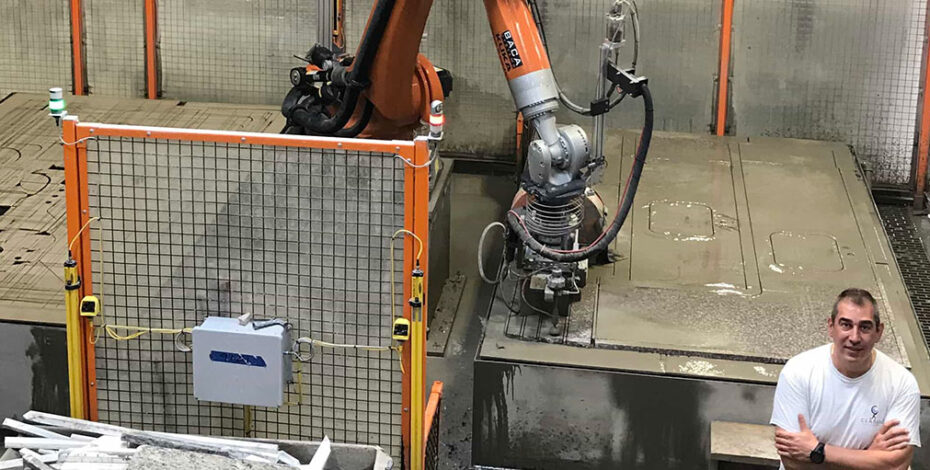

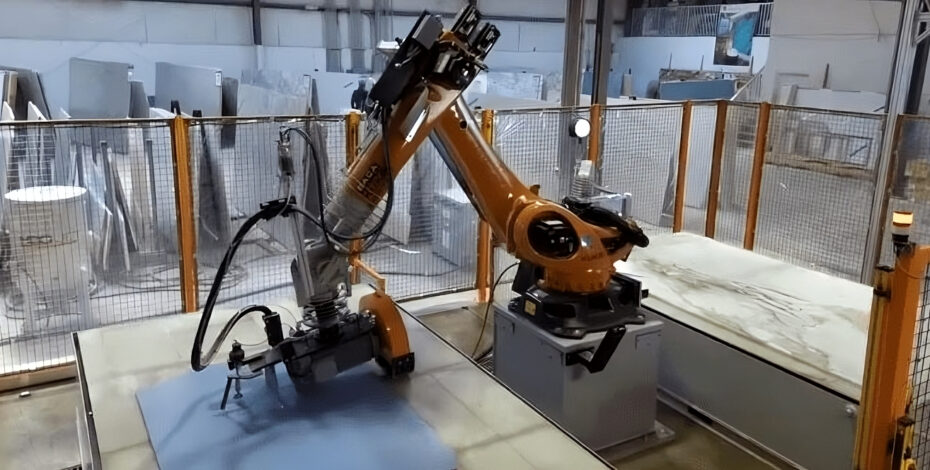

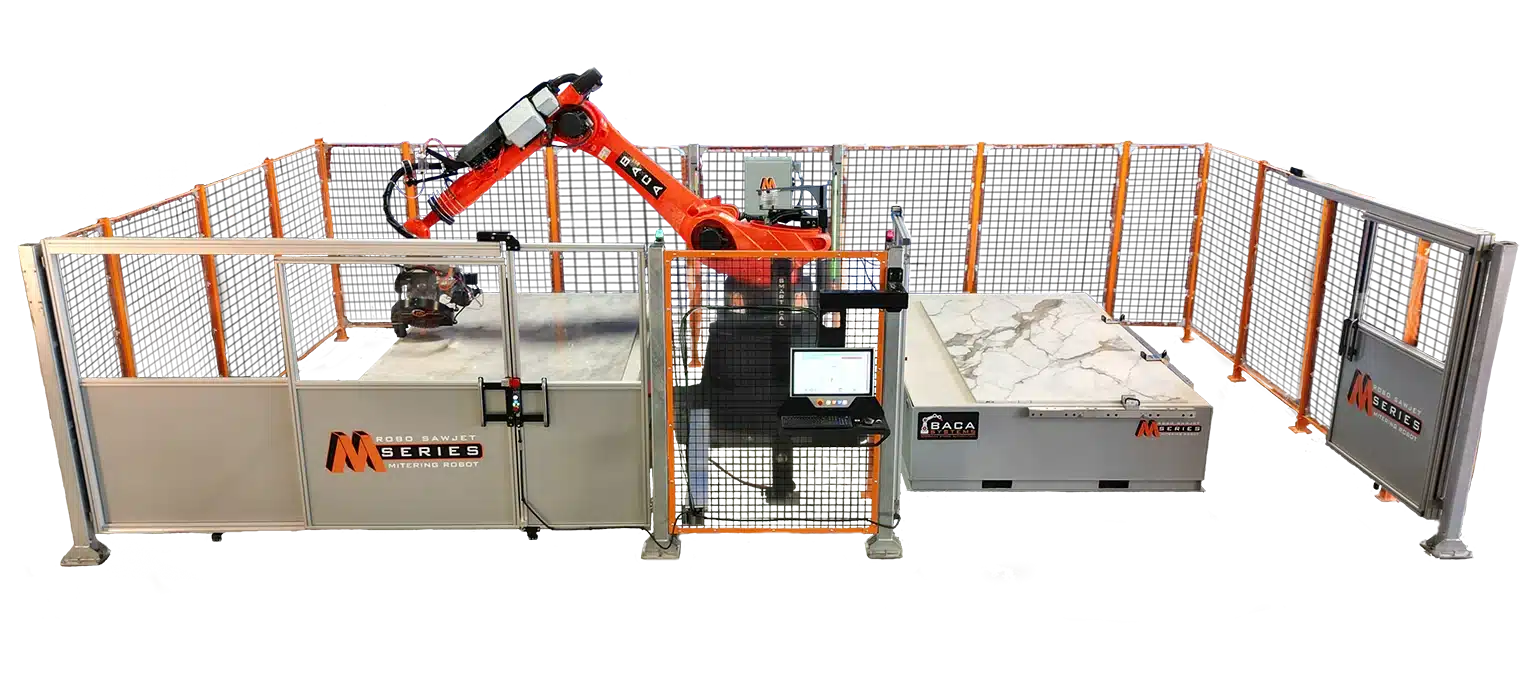

The M Series 240 delivers full miter capability with saw and waterjet, full table blade coverage, automated calibration, and auto start for 100% uptime. Built for superior reliability with minimal maintenance, it features easy-to-use software, a small footprint, and upgradeability to a second table.

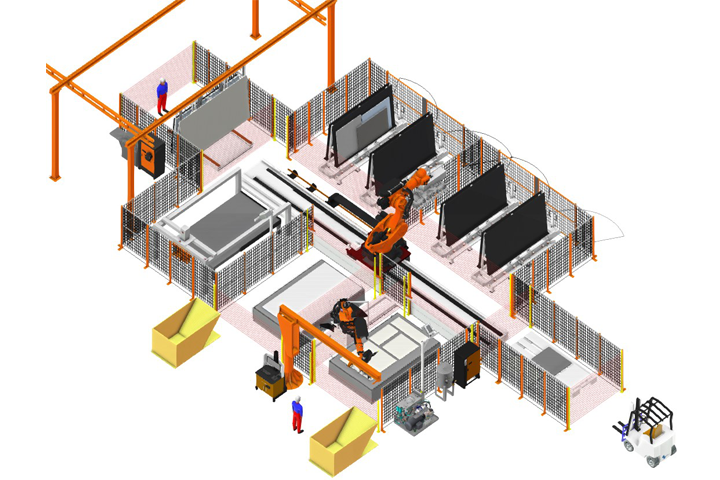

Learn How Automation Will Increase Profitability

Come see firsthand how digital fabrication equipment increases quality and safety of your operation, decreases labor & increases material yield.