Semi-Auto Tite Rack

Slab Storage

Semi-Auto Tite Rack

Slab Storage

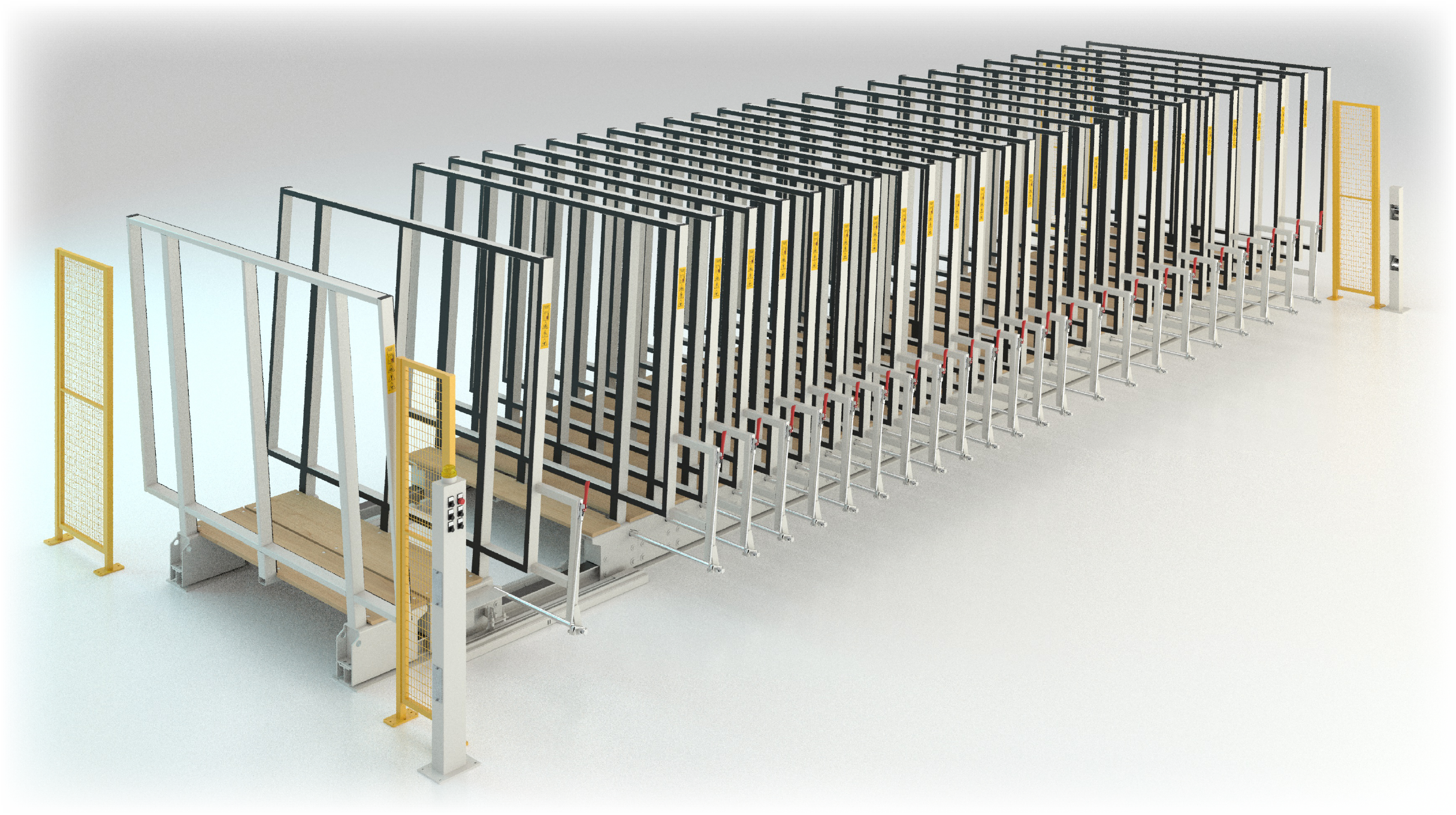

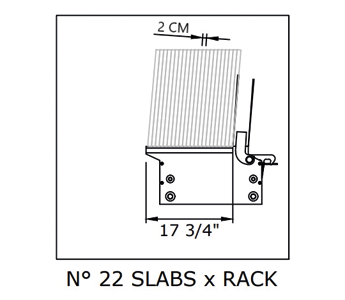

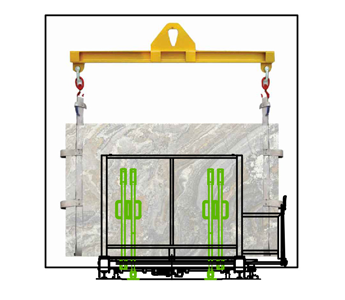

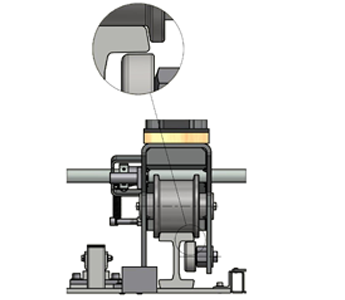

Tite Rack is a vertical storage system designed for safe and compact slab storage of marble, granite, engineered stone and ceramic slabs. The system is composed of moveable frames which slide over properly dimensioned rails, which are compacted among them and allow the operator to create the space needed for loading/unloading each individual rack.

COMPACT

STORAGE

STORAGE

SAVE

SPACE

SPACE

FULLY

CUSTOMIZABLE

CUSTOMIZABLE