Automated Slab Handling

Slab Storage

Automated Slab Handling

Automated Systems

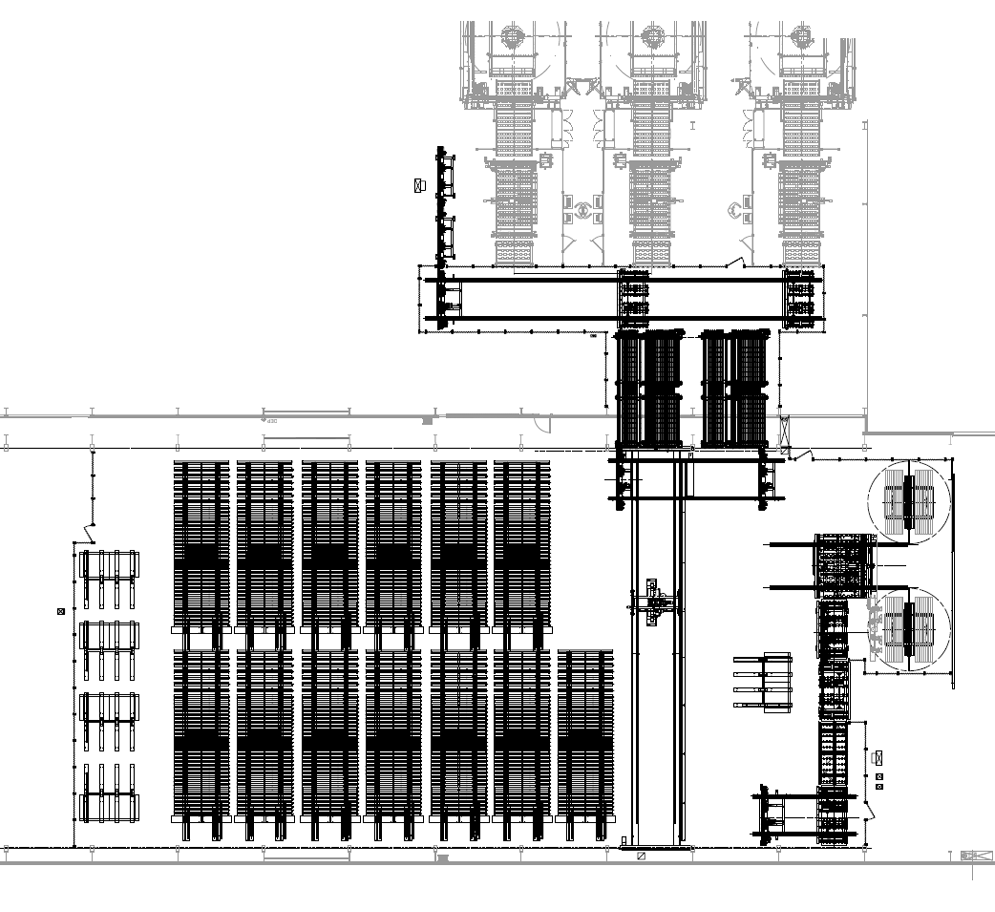

Discover the Automated Slab Handling system, a 6-axis gantry portal crane revolutionizing slab management. Increase safety by eliminating manual slab handling, photographing of slabs, and automated loading of sawing solution(s). Reduce floor space by 75% with compact material storage. Boost material yield through efficient inventory control, reducing breakage, and maximizing remnants utilization.

SAFELY

HANDLE SLABS

HANDLE SLABS

SAVE 75%

SHOP SPACE

SHOP SPACE

REDUCE

BREAKAGE

BREAKAGE