Miter X 2.0

Dedicated Miter Machine

Miter X 2.0

Dedicated Miter Machine

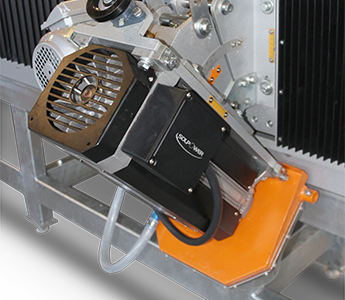

The Miter X 2.0 is equipped with a 25-HP saw motor, making it the most powerful miter saw in its class. The stronger motor allows for faster processing speeds on all countertop materials and provides the power required to cut the hardest materials, such as quartzite, with ease. With over 250 machines installed in North America, the Miter X is the right solution for your miter needs.

25-HP Motor

VFD

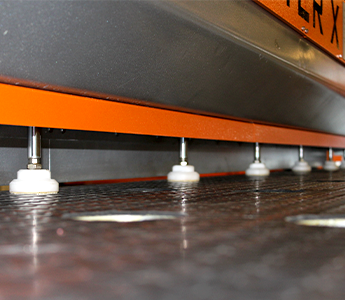

Easy 2 Use