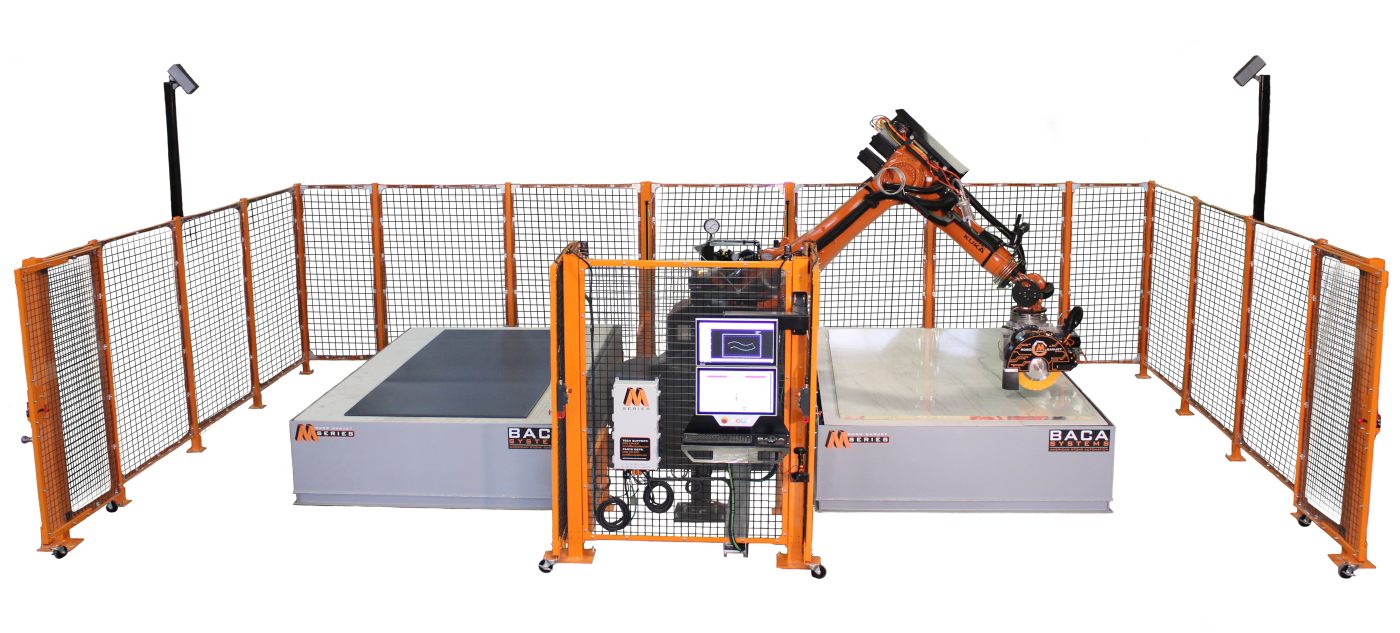

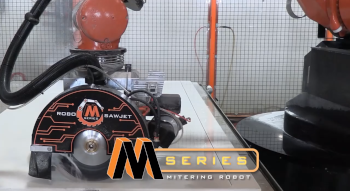

M Series

Robotic SawJet

M Series

Robotic Sawjet

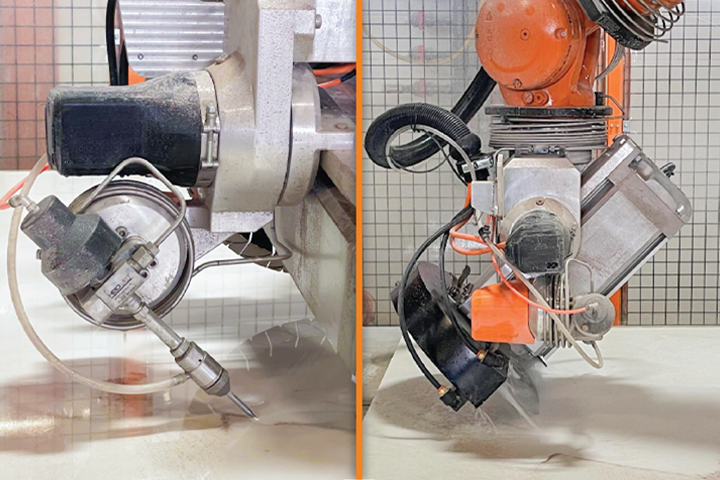

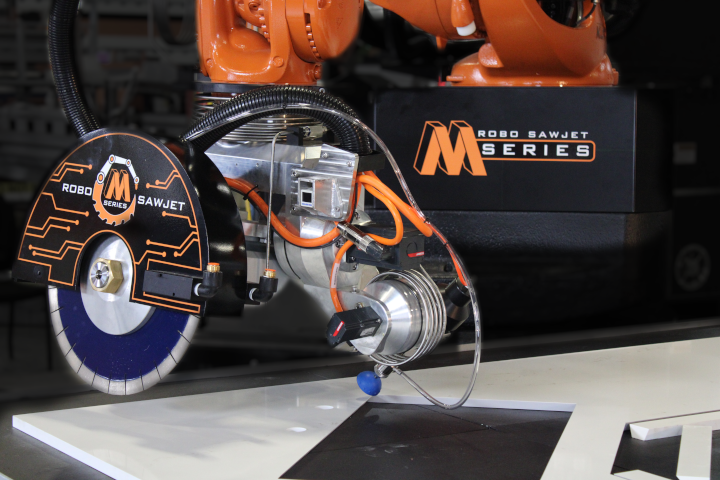

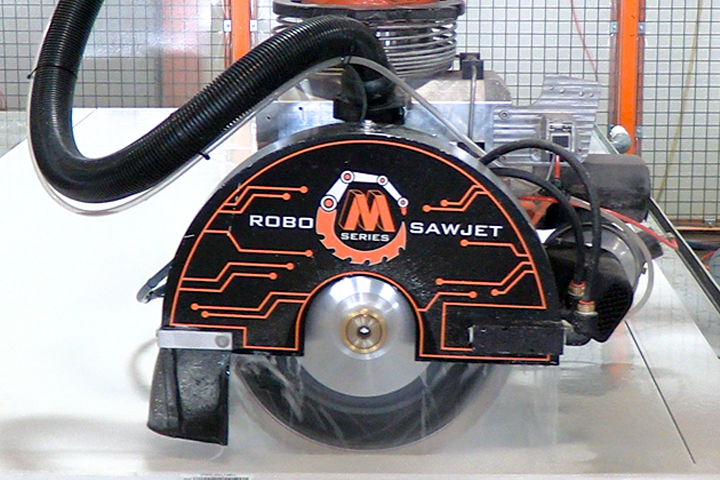

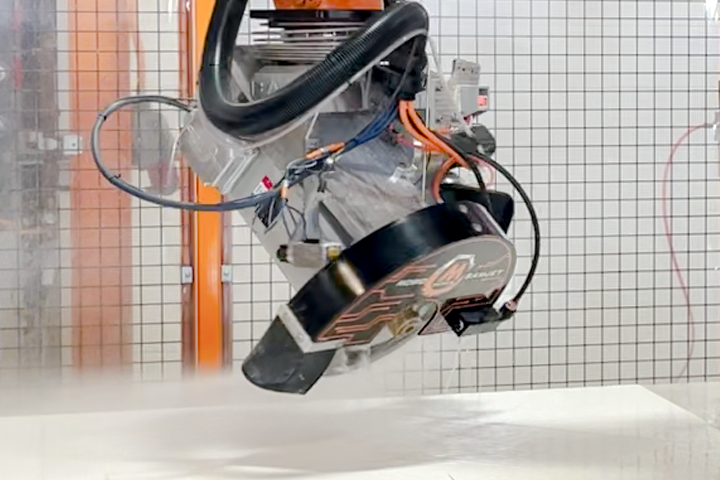

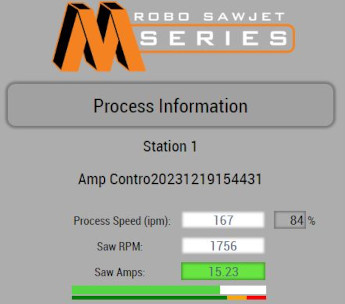

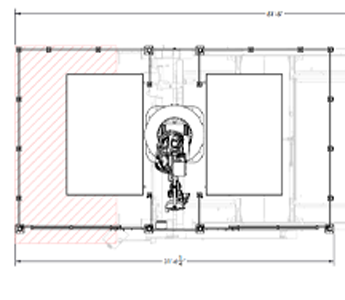

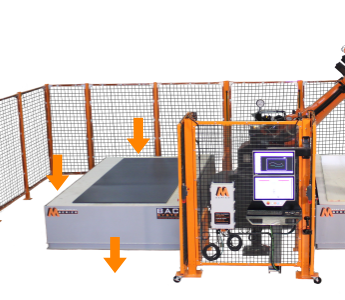

The M Series is an advanced cutting machine that offers full mitering capabilities in a single unit, accommodating both sawblade and waterjet mitering. With a generous saw and jet mitering envelope, it handles super jumbo slabs effortlessly. Utilizing efficient programming through Alphacam with BACA’s custom toolbar makes programming easy, precise multi-point slab thickness adjustment for mitering, and a remarkable patent pending auto-calibration process.

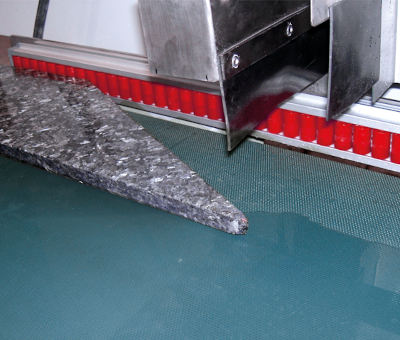

SAW & JET

Mitering

Mitering

SUPERIOR

RELIABILITY

RELIABILITY

MINIMAL

MAINTENANCE

MAINTENANCE