Autocut Line

AUTOMATED SYSTEMS

Autocut Line

AUTOMATED SYSTEMS

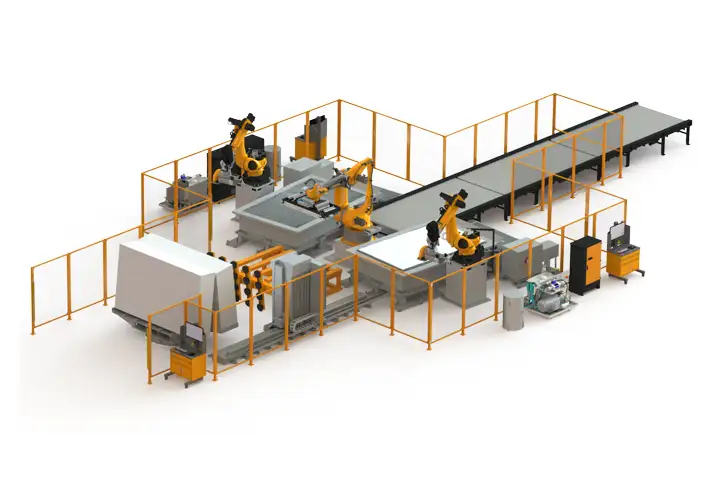

The Autocut Line is tailor-made for high-volume fabricators aiming to achieve a remarkable 2,000 SQ FT per shift with minimal labor. Featuring the robotic loading and unloading of the Robo SawJet, Autocut is the epitome of maximizing operational efficiency. These systems are fully customizable, allowing fabricators to fine-tune them to meet their specific requirements and elevate their production capabilities.

MAXIMUM

PRODUCTION

PRODUCTION

REDUCE

LABOR

LABOR

FULLY

CUSTOMIZABLE

CUSTOMIZABLE