Athena

MULTI EDGE POLISHER

Athena

MULTI EDGE POLISHER

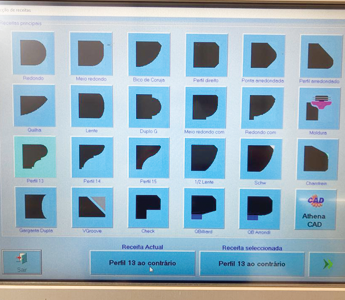

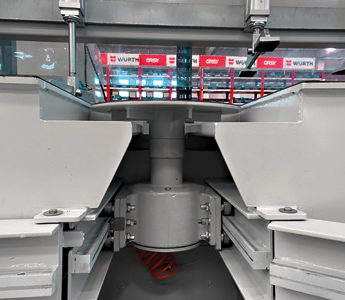

Single-head CNC edge polishing machine completely automatic for marble, granite, engineered quartz and ceramic for straight edges and shaped edge profiles.

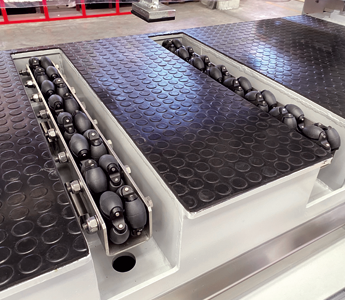

SMALL FOOTPRINT

EASY 2 USE

MONOBLOC CONSTRUCTION