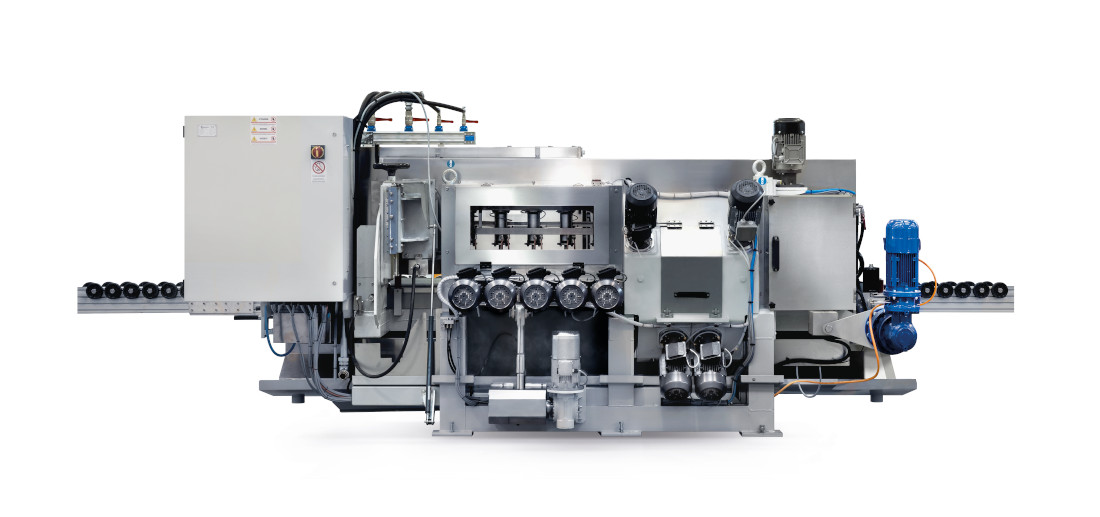

Penta

HORIZONTAL EDGE POLISHER

Penta

HORIZONTAL EDGE POLISHER

Designed according to the up-to-date concepts and structural principles, the automatic multi-spindle belt polishing machine model PENTA, is remarkable for its high productivity and its high-quality performances on every kind of marble, granite, engineered stones and ceramic. Its complete equipment allows it to perform all the finishing operations on the materials used in the countertop industry.

1-PASS

POLISHING

POLISHING

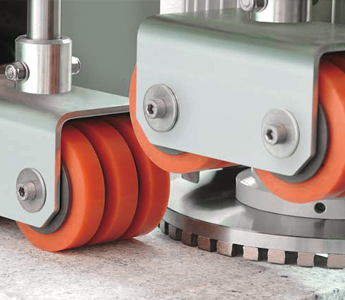

OPTIONAL CALIBRATOR

VERTICAL

SPINDLE

SPINDLE