Both 5- and 6-axis CNC routers are great stone cutting machines, but it may be difficult to decide which one is the better investment for your purposes.

At BACA Systems, we tailor our equipment to the specific requirements of stone cutting applications, so we are familiar with the full capabilities of both systems. While a 5-axis cutter can handle most of the everyday cuts—such as traditional countertop cuts—more complex cuts may require the performance advantages provided by an extra sixth axis. This comparison article will help you decide whether you need a 6-axis or a 5-axis stone cutter for your operation.

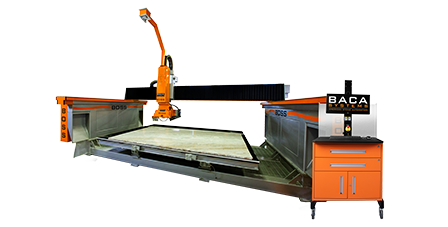

5-Axis CNC Stone Cutters

5-axis CNC routers, such as BACA’s Boss Saw 2.0, can easily and precisely cut through granite, marble, quartz, and other ultracompact slabs. Of course, BACA’s Boss Saw has a few unique characteristics, such as the ability to add a GAS bit for drilling faucet and sink openings.

A 5-axis machine will be able to handle the most common countertop cuts. But let’s say you need to create an intricate, custom design for a meticulous homeowner, or create complex shapes for a business countertops. The countertop itself may not even be smooth. Plus, you know that completing these complex designs on a 5-axis stone cutting machine will take more time. How do you ensure you can take these custom designs from concept to reality in your shop, and what other benefits might come with upgrading to a 6-axis stone cutting machine?

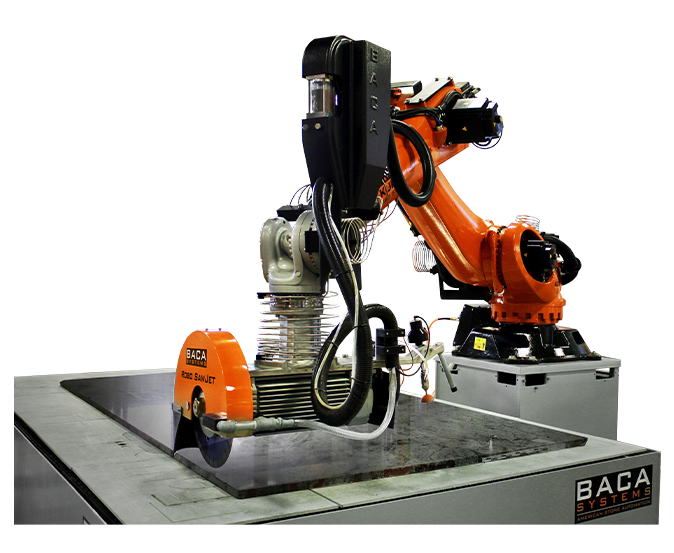

6-Axis CNC Stone Cutters

A 6-axis CNC stone cutter, like BACA Systems’ Robo SawJet 2.0, allows for the completion of an entirely new level of cuts, ensuring that no design is too detailed or unique to be cut. In addition to executing more intricate designs, 6-axis machines can reduce production time by creating faucet and sink holes automatically and at the same station, removing the need to change a bit or move the material to a different station.

BACA’s Robo SawJet is designed to leverage the performance of a 6-axis router against the multiple stages of stone cutting and fabricating. For instance, high-pressure coils on each axis allow for faster movement and decrease the time between cuts, while a separate waterjet cutter performs precision finishing of already-cut pieces so they do not have to be moved to another station for finishing.

Cost Considerations

6-axis CNC stone cutting systems are often more expensive than 5-axis systems, simply because of the additional functionality. However, there are other cost factors besides the sticker price.

For instance, while a 5-axis machine is cheaper upfront, your operation may incur additional costs in terms of time and equipment if you’re constantly moving materials between stations to finish smaller-cut pieces and drill openings, or if you’re configuring equipment for more finely detailed cuts that a 5-axis machine can’t complete.

If your outfit produces mostly standard-cut countertops and other stone fabrications, a 5-axis CNC machine equipped for countertop-specific functions (like a GAS drill bit) will likely suffice. However, if your operation normally requires a good amount of highly detailed cuts, or if you process a lot of intricate, custom stone designs, a 6-axis CNC system, like BACA’s advanced Robo SawJet, might be a better investment. Machines like the Robo SawJet can make any cut from practically any angle, have the ability to create faucet and sink openings in the same place, and require less maintenance over time due to their advanced engineering.

Visit BACA to See Our 5- & 6-Axis Stone Cutters

If you’re thinking about purchasing a 5-axis or 6-axis CNC stone cutter, but you’re still not sure which one will serve you best, consider taking an exciting, educational trip to Detroit and meeting our team at BACA Systems’ state-of-the-art facility. Fly to Detroit soon, and let us show you how to reduce your material and labor costs, complete projects up to four times faster, and boost your profit margins. Or, contact us today with questions or to request a quote.