Yes, you can cut marble with a 3-axis CNC router, although fabrication success depends on the type of bit used on the router and the thickness of the marble. Routers are more suitable for softer stones like marble and slate, whereas harder stones may require more robust machinery, like a sawjet.

Bit Requirements

When cutting marble with a 3-axis CNC router, you can use an advanced-grade carbide bit, but diamond-tipped bits are recommended.

Carbide bits are effective for softer materials but may wear out quicker with harder stones. Comparatively, diamond-tipped bits maintain sharpness longer and can handle the hardness of marble more efficiently, resulting in cleaner cuts and prolonged tool life.

Thickness Limitations

Material thickness will vary based on the type of bit that’s used to cut the marble. As a general practice, you should not use marble slabs exceeding three inches (75 mm) with 3-axis CNC routers; otherwise, you risk quality.

Carbide bits are generally suitable for marble slabs up to one inch (25 mm). If you exceed this, you risk shortening the bit’s expected wear rate and chipping the marble. Diamond bits are recommended for slabs exceeding two inches (40 mm) because they are more durable and can maintain precision over extended use.

Our Recommended 3-Axis Machine

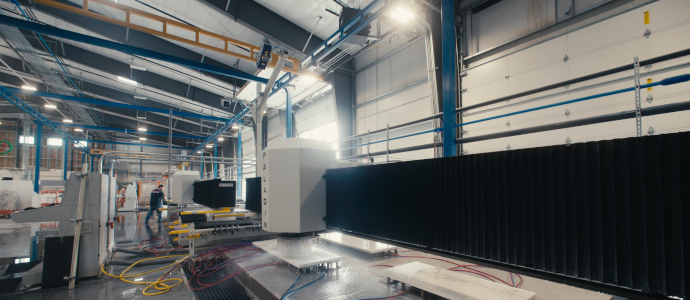

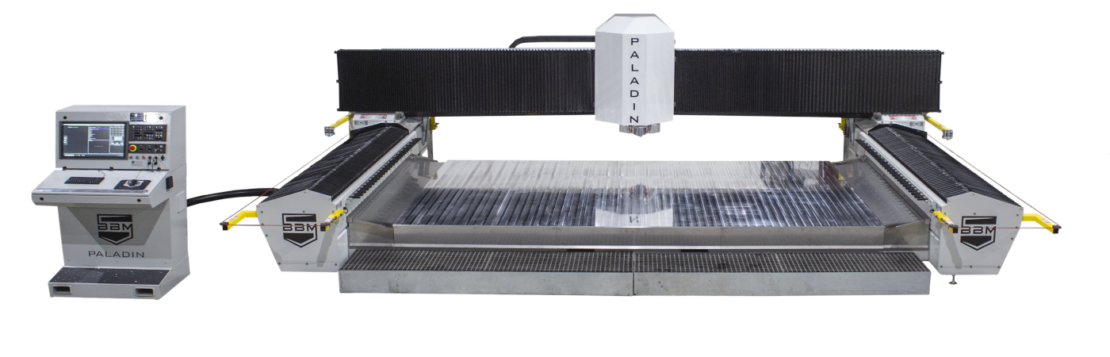

If you’re looking for a 3-axis CNC machine that can handle simple stone fabrication processes like polishing, we recommended BACA’s Paladin, a large, open-format, high-rail gantry milling machine.

The Paladin is designed with rugged environments in mind, as it’s constructed with fabricated heavy-gauge welded steel and a galvanized base. The linear axes are laser-aligned and compensated, and all structural components are stress-relieved to ensure precision and safety.

Other features of The Paladin include:

- 8’ x 13’ Aluminum Washdown Table/Workspace

- 20-HP Spindle

- Dual-Vacuum System

- Jog Pendant for Manual Positioning

- Ball Screw Drive System for Reduced Maintenance

- PC-Based System With High-Resolution LCD Monitor

- Laser Projection System With Calibration Targets

- Two Easy Access Doors

- 60-Position Tool Change Rack

Learn More About Our Equipment

BACA Systems is an award-winning manufacturer that has been developing innovative robotic stone fabrication equipment for almost a decade. Since our founding, we’ve been committed to helping our customers improve quality, profitability, and productivity.

Please contact us today if you have questions about our stone cutting solutions, or visit our website to learn more about our Fly to Detroit opportunity, where you can visit our shop (at our expense) to see our equipment in action.