In the past, fabricators hand-cut their valuable stone, which is a slower and riskier process. These days, more and more fabricators are upgrading their operations to include robotic cutting systems—and there’s a good reason for it. In this article, we’ll explore some of the many benefits of robotic stone-cutting equipment.

Robotic Systems Reduce Waste

PC software easily and quickly accommodates detailed planning to maximize material usage, which is important when dealing with expensive granite, marble, and other popular types of stone. The program automatically determines the most strategic cuts to minimize material wastage.

A robotic sawjet also removes the need to continually relocate saw-cut pieces in-between cuts; the robot can complete even highly detailed cuts with the waterjet in places where a handheld or CNC saw would damage the adjacent material.

Robotic Cutting Equipment Improves Productivity

Compared to other stone-cutting methods, a robotic sawjet increases the cutting range of motion and maximizes yield, ultimately leading to higher profits. No matter the degree of skill a craftsperson possesses, it can never match the tireless precision delivered by a programmable robot.

Robotic Stone-Cutting Systems Are Easy to Integrate

Lastly, integrating robotic stone-cutting equipment into your shop is easy. With certain equipment, like BACA Systems’ Robo Sawjet and Robolution Pro, you can add them to your current production lines without changing the existing footprint. And many robotic stone-cutting systems are adaptable and able to scale to the size of the fabrication project currently in progress, increasing production, safety, and profitability.

BACA Systems’ Robotic Cutting Solutions

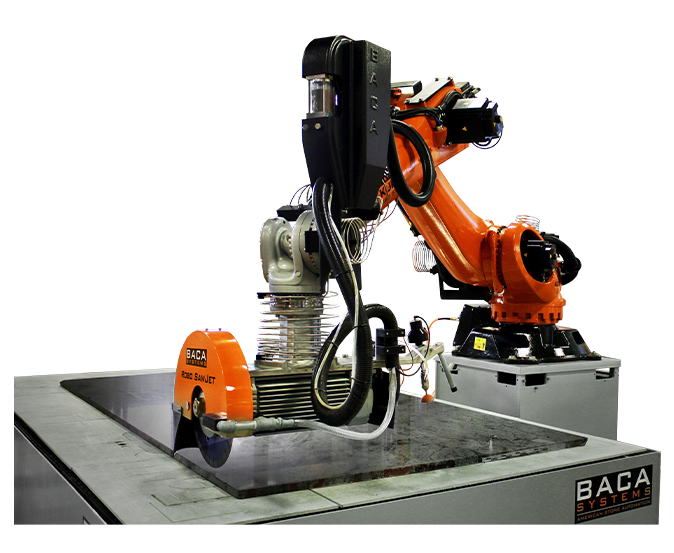

BACA Systems offers several robotic cutting solutions, our most popular being the Robo Sawjet 2.0.

Our Robo Sawjet comes standard with a 26-HP motor, a 16-inch saw blade, variable frequency drive (VFD) technology, and, of course, a high-pressure water jet that meticulously completes corner cuts where the saw blade doesn’t quite reach. All cuts and miters are made fast with exacting precision.

It’s also fitted with six separate axes, each with high-pressure coils that allow the robot to move quickly from one cut to the next. Plus, a dual table set-up allows technicians to load or unload one table while the robot is operating on the other, which allows the system to run constantly to optimize production.

Learn More About Our Solutions

BACA Systems continues to be the leading provider of stone automation and countertop fabrication machines in the United States. We’re honored and proud that our Robo Sawjet is the most widely used robotic sawjet on the market today.

If you’re a stone fabrication shop owner or manager looking to upgrade your operations, don’t hesitate to contact our helpful team. We’re happy to answer any questions you may have about robotic cutting systems and help you select the best option for your shop. We’re committed to providing the assistance you need to catapult your fabrication success to new heights!