BACA Systems is proud to be a leading manufacturer of robotic cutting systems. Our systems offer many benefits, including improved efficiency, enhanced safety, and reduced waste.

Even if you’re a skilled craftsperson, a robotic sawjet cuts stone far more safely, quickly, and precisely than traditional hand-cutting methods. In fact, compared to diamond cutting blades and conventional wet saws, robotic sawjets easily slice through granite, marble, and other hard stones in far less time and with less material wastage.

If you’re looking for ways to increase your fabrication shop’s productivity, consider purchasing our best-selling robotic sawjet—the Robo Sawjet 2.0

What Is the Robo Sawjet 2.0?

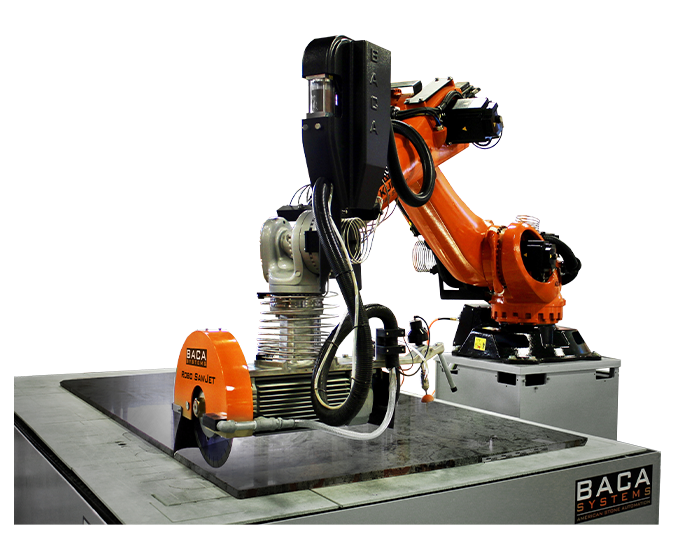

The Robo Sawjet 2.0 is used in hundreds of fabrication shops across North America. This six-axis robotic cutting system features intuitive PC-based software to make more precise cuts, is suitable for small shops, and requires minimal maintenance. The Robo Sawjet 2.0 is also designed with a 26-HP saw with a 16-inch blade to give you the best power and speed possible.

In addition to its precision, small footprint, low maintenance requirements, high speed, and impressive power, the Robo Sawjet 2.0 provides other benefits for stone fabricators.

Let’s take a closer look at some of them.

Easy Programming

The Robo Sawjet 2.0 features easy-to-use, PC-based RoboCut and RoboCommander software. These software packages control the KUKA KR 210 robot with extreme accuracy and fluency, showcasing the flexibility of abrasive waterjet technology while incorporating the simplistic operation of a traditional saw.

With its intuitive interface, the RoboCut software integrated into the system allows operators to generate complex, multi-task cutting paths with just a few clicks. And, you can do the programming on the production floor or remotely in your office.

Reduced Handling

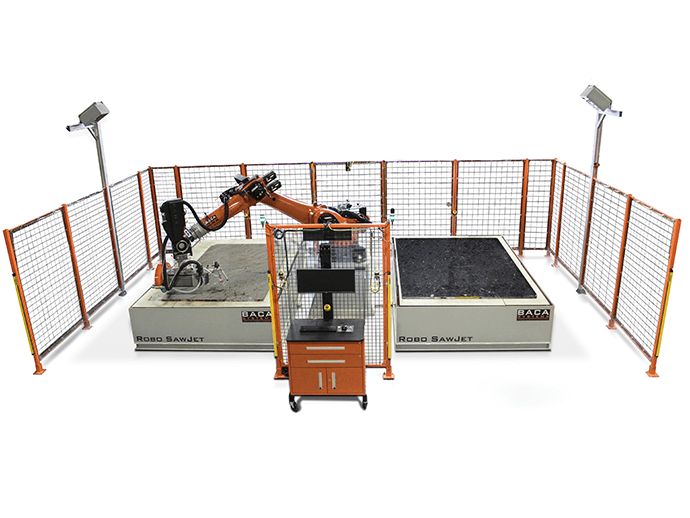

The Robo SawJet 2.0 quickly and accurately cuts arcs, faucet openings, sink holes, and more on a single worktable, decreasing the need to repetitively relocate pieces to secondary cutting stations.

Making these cuts during a single sawing process reduces wear and tear on CNC machines and significantly cuts down on workstation bottlenecking, freeing up your team’s time to accomplish other tasks.

Plus, BACA’s Waterjet Made Easy maintenance program ensures that all intensive upkeep is completed by our trained technical team, further freeing up your schedule to meet other goals.

Maximized Usage of Stone

Did you know the Robo Sawjet 2.0 handles all materials, including granite, marble, and ceramic? It’s true. The Robo Sawjet 2.0’s integrated RoboCut software automatically calculates where waterjet and blade cuts are required to maximize material usage.

It only takes a few simple, quick mouse clicks, and the robotic cutting system is ready for hands-free operation. There’s no need to relocate already-cut pieces between basic and finishing cuts, and you won’t have to worry about the robot damaging any proximal material.

Increased Productivity

Finally, this robotic cutting system features six axes, each equipped with high-pressure coils that ensure speed and smooth movement. Plus, the KUKA LR 210 robot is designed to operate for 10,000 hours (about five years for most shops) before needing its first oil change. Compare this to the weekly maintenance required to keep old-school gantry sawjets operating efficiently.

The dual-table Robo SawJet 2.0 also permits loading and unloading in one workstation while the robot performs exacting cuts on a secondary table, enabling constant cutting that significantly increases your production levels.

Request a Live Demonstration or Product Quote Today

BACA Systems is a world leader in robotic sawjet technology for stone fabrication processes. Our innovative systems are adaptable and provide ultimate reliability, unmatched productivity, and superior cost-effectiveness.

Are you curious about our Robo Sawjet 2.0? If so, fly to Detroit, MI, for a live demonstration. We cover all expenses. During your demo, we’ll give you a tour of our facility, show you several fabrication shops that use our products, and provide free demos for any equipment you’re interested in.

If you’re not ready for our Fly to Detroit experience, please contact us today to request pricing or more information. We look forward to hearing from you!