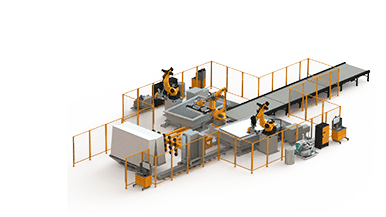

At Baca Systems, we embrace technology. Our leading-edge robotic material handling and cutting systems, combined with state-of-the-art production planning software, ensure quality products at the best prices. By implementing a high volume material handling and Fully Automated Cutting Line, we not only increase operational efficiency, but we make sure our customers get the products they need on time and with the highest level of precision and excellence.

How Automation Benefits Our Customers

Automation combined with robotics has revolutionized how we do business, providing numerous advantages that directly translate to benefits for our customers.

Increased Production Output

Our team at Baca Systems understands the needs of our customers. Using robotics, we can maintain a consistent, high-output speed production rate that does not require constant supervision. Not only can we produce existing products more rapidly, but with a change in programming, we can quickly introduce new products to the process without disruption. Fully Automated Cutting Line

Increased System Versatility

With automation, multi-step processes can be carried out quickly and efficiently, reducing overall time to market and allowing us to maintain end-to-end production in-house. We can easily retool and reposition robots for new programs, switching between products, processes or production volume as demand dictates. One of the most useful advantages of robotics is the ability to instantly adapt to new operations with no learning curve.

Improved Quality

Automation results in fewer errors than manual processes. Precision is increased to tighter tolerances and greater consistency. Our automated systems allow factory communication in real-time, meaning that we can respond and adapt to any issues instantly if they arise, maintaining our strict quality processes and ensuring your product is ready on time.

Reduced Lead Times

Implementing automated inventory management systems means that materials are available when needed, reducing the lead time necessary to order and receive supplies and ensuring that our customers keep their projects running on time and on budget.

Reduced Operating Costs

Robotics reduces the dependence on skilled labor for repetitive tasks. Robots can do the work of multiple employees, reducing labor costs and optimizing production output. With CNC guidance, cutting accuracy is increased while waste and energy costs are decreased. Minimizing waste and energy usage means a smaller environmental footprint and reduced material costs that can be passed on to our customers.

How Production Planning Software Benefits Our Customers

While you may think that production planning only provides internal efficiencies, there is a distinct trickle-down effect that directly impacts our customers. At Baca Systems, customer satisfaction is vital to our business, and meeting or exceeding their expectations is of utmost importance. Production planning software enables our high volume material handling and cutting solution to continue to deliver efficiently, reliably and without schedule delays.

A few of the ways production planning software benefits our customers include:

- Adaptive scheduling – Unforeseen events can significantly impact production schedules. Production planning software aids in disaster recovery, minimizing schedule delays by quickly adapting to a change in facilities or a change in demand. Not only can it facilitate the changes, but the software can suggest multiple scenarios, including the most expedient or cost-efficient options.

- Consolidated scheduling – By integrating all facility production schedules, including both production and distribution, all processes can be streamlined and optimized to ensure every product for every customer is delivered on time.

- Automated ordering – By tracking material prices from hundreds of suppliers, purchasing can be optimized to leverage lower costs as they occur, passing on those savings to our customers.

Continuous improvement – We don’t rest on our laurels. At Baca Systems, we implement the latest in technology solutions to continue to improve our quality, our efficiency, and our customer service. The data our systems collect allow us to do in-depth data analysis that enables us to innovate and improve continuously.

Don’t wait to reinvent your granite processing line. Contact us today at BACA Systems to ask about our Boss Saw 5 axis CNC router. Explore this and other CNC router machine options to discover how you can upgrade your facility and create beautiful, custom countertop pieces for less. Invest in a reliable machine to keep your business moving forward.