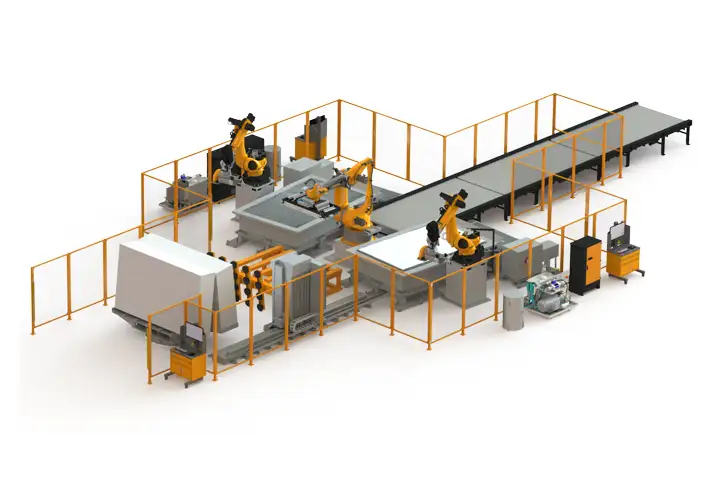

BACA Systems is committed to revolutionizing the stone fabrication industry through advanced technology and innovation. Our cutting-edge robotic material handling and precision cutting systems, combined with state-of-the-art production planning software, deliver unparalleled efficiency, safety, and accuracy for your operations.

By implementing our high-volume material handling solutions and fully automated cutting lines, fabricators can significantly boost productivity while reducing labor requirements and minimizing risks. Our comprehensive approach ensures you achieve maximum operational efficiency, delivering top-quality products on time with the highest level of precision and craftsmanship.

Discover how BACA Systems’ innovative solutions can transform your stone fabrication processes.

How Automation Benefits Our Customers

The stone fabrication process has traditionally been labor-intensive, time-consuming, and dependent on skilled labor. However, with labor shortages affecting industries across the board, automation has become a game-changer.

From robotic cutting systems to fully automated material handling solutions, our equipment empowers fabricators to increase production, reduce costs, and improve workplace safety. Here’s how automation benefits the stone fabrication industry:

Increased Safety

Safety is a top priority in any fabrication shop. BACA Systems’ stone fabrication machines are engineered to minimize manual handling, significantly reducing the risk of workplace injuries. Fully automated systems, such as robotic loaders and unloaders, enhance safety by handling heavy slabs and materials with precision and reliability. This not only protects employees but also boosts overall efficiency of a machine by decreasing time for loading and unloading.

Reduced Operating Costs

Automation with robotics and CNC technology eliminates the need for skilled labor in repetitive tasks, allowing fabricators to optimize labor costs.

For example, robots can perform the work of multiple employees, streamlining production processes and reducing overhead.

Our innovative SawJet cutting systems save fabricators 3 to 4 hours per slab compared to manual cutting, particularly for complex features like sinks, arcs, radii, and faucet holes. Additionally, the integration of waterjet technology eliminates blade over-travel, ensuring precise cuts to a defined point. This improvement saves 10 to 20% on material costs by maximizing the usable area of each slab.

Increased Output & Reduced Lead Times

Automation drives higher productivity with the same labor input. Fully automated systems, like those developed by BACA Systems, further increase output by streamlining every step of the fabrication process, from cutting to polishing. This efficiency reduces lead times, ensuring fabricators can deliver finished countertops faster and keep projects on schedule and within budget.

Improved Quality

Automated equipment delivers unmatched precision, producing a finished product that exceeds the quality of manual stone fabrication. BACA Systems’ machines are designed to cut, shape, edge, and polish with consistent accuracy, eliminating errors and ensuring a flawless final stone product every time.

Transform Your Fabrication Business With BACA Systems

Automation is no longer a luxury in stone fabrication—it’s a necessity. By integrating advanced robotic and CNC systems, fabricators can reduce costs, improve safety, and deliver exceptional results. At BACA Systems, we provide not only the machinery but also comprehensive installation, service, and support to ensure your success.

Discover how our innovative solutions can transform your stone fabrication operations. Visit our website to learn more about our fully automated systems and cutting-edge technology.