BACA Systems offers fast, accurate, and adaptive cutting technology for stone fabricators. Investing in our waterjet cutting machines will increase production while elevating product quality and enhancing workplace safety.

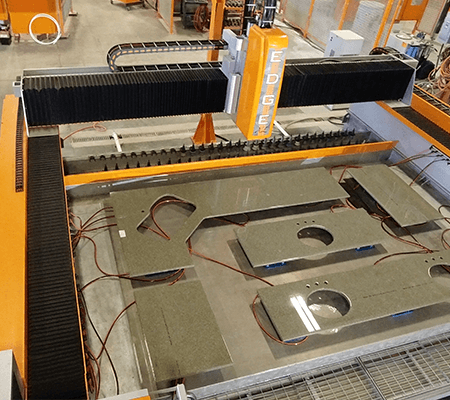

Edge XL

The Edge XL is a PC-based 3-axis waterjet cutting machine that makes slicing through the hardest stone slabs effortless and precise. It’s easy and fast to program, features a large, open design, and simplifies even the most challenging stone-cutting projects.

This powerful yet quiet sawjet is designed as a wash-down machine and features an 8’ x 13’ cutting table and a 60-tool changing rack. In addition to its many features, it was manufactured for smooth, rapid, and safe operation and requires very little maintenance when used properly.

Power Specifications:

- 220 V, 3 Phase, 100 Amps

Water Specifications:

- 15 GPM at 35 PSI

Air Specifications:

- 20 CFM at 100 PSI

Robo Sawjet 2.0

With three additional axes than the Edge XL, the Robo Sawjet 2.0 delivers expanded-angle cutting power. It’s BACA’s original waterjet, and there are more than 600 currently in use by stone fabricators throughout North America. Benefits of this highly accurate stone milling machine include:

- Low Maintenance Requirements

- Small Carbon Footprint

- PC-Based Software

The Robo Sawjet 2.0 can also be upgraded with a secondary cutting table, allowing your team to load one table with a fresh slab while another slab is in production. It’s so satisfying to stand back and watch this fluent machine slice through marble, granite, and other fine stone.

Power Specifications:

- 480V, 3 Phase, 80 Amps (Robot)

- 480V, 3 Phase, 100 Amps (Pump)

Water Specifications:

- 4 GPM at 40 PSI (Cutting Water)

- 5 GPM at 35 PSI (Saw Water)

- 2 to 4 GPM at 35 PSI (Pump Cooling)

Air Specifications:

- 1 CFM at 85 to 100 PSI (Robot)

- 3 CFM at 60 to 100 PSI (Garnet System)

3-Axis Versus 6-Axis

BACA offers 3- and 6-axis waterjet cutting machines, each offering unique benefits.

3-axis routers like our Edge XL operate in three directions: X (left/right), Y (forward/backward), and Z (up/down), but cannot rotate around the axes. These routers are best suited for less complex applications requiring straight lines for trimming. 3-axis routers can be pre-programmed and automated to speed up production.

Comparatively, 6-axis routers like the Robo Sawjet 2.0 have more degrees of freedom (wider range of movement). A 6-axis router can move left/right, forward/backward, and up/down like a 3-axis, and it also operates on the A-axis (tilt) and B- and C-axes (rotation), making it ideal for more advanced operations that require better flexibility and precision.

Both the Edge XL 3-axis router and the 6-axis Robo Sawjet are easy to program, require little maintenance, and are designed for precision and long-term value.

Learn More About Our Stone Water Cutting Machines

If you need help selecting the right CNC router for your shop, reach out to BACA Systems.

Founded in 2014, BACA Systems is a leading provider of stone automation and robotic countertop fabrication machines. Our goal is to ensure that our valued clients are equipped with the best and fastest stone-cutting solutions. If you need help selecting the right waterjet cutting machine for your shop, please get in touch with our friendly professionals today.