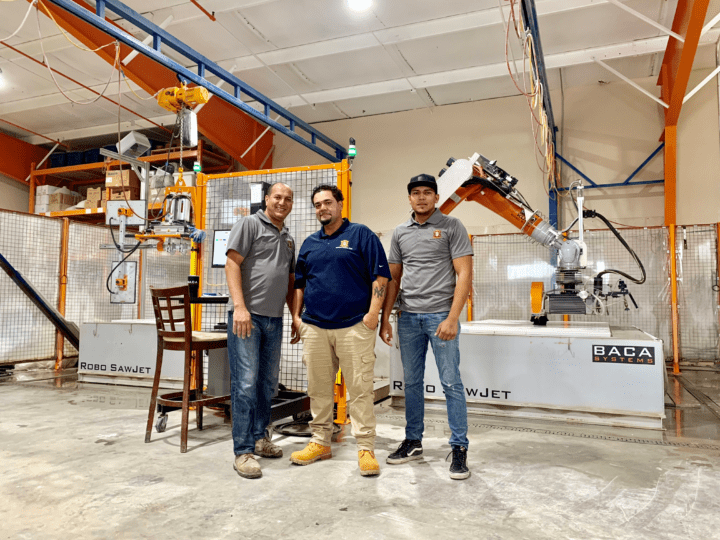

Finds the Perfect Robotic Solution

It took time to find the right fit, but Trademark Universal Stone has transformed its fabrication capabilities using state-of-the-art robotics technology.

Founded in Louisville, Kentucky, in 2009, Trademark quickly became one of the largest stone fabricators in the area. Business grew at such a fast pace in recent years that the fabrication shop simply couldn’t cut stone fast enough.

“We got to the point that we couldn’t take on any more business because we couldn’t keep up with the amount of work we had,” owner Henry Berroa said.

Berroa started looking for technological solutions to help keep up with demand. After a false start with a stone fabrication robot from a competing manufacturer, the company bought a BACA Robo SawJet in 2017. Since being installed, the RoboSawJet has doubled Trademark’s production capacity.

“We’re cutting so fast that we were able to reduce overtime and increase output,” Berroa said. “We’re putting out about 1,000 square feet per day with one shift. We have more install crews now and are generating more income. Our company has pretty much doubled.”

The Robo SawJet incorporates a precision KUKA Robotics industrial robot. Equipped with a high-pressure abrasive waterjet and a 26HP direct-drive saw, it can cut a standard 40-square-foot kitchen countertop with sink hole from a slab within 15-18 minutes. This is half the time of other machines.

“We’re cutting so fast that we were able to reduce overtime and increase output”

Increased Yield

The combination of the waterjet and saw provides superior cutting accuracy. Coupled with sophisticated on-board software that optimizes cutting patterns, this boosts the yield from individual slabs and allows customers to save an average of 20 percent on material costs annually.

“What is really cool is that you’re able to get more out of the waterjet cuts and the saw cuts,” Berroa said. “Because of that we’re able to avoid a lot of the overcuts, which means we have a lot better yield. We’ve been able to save a lot on material costs.”

The Robo SawJet is a dual-table system, which allows one table to be loaded while a slab is being cut on the other. It uses a durable H2O jet pump, which was originally designed to hold up under demanding 24-hour per day automotive manufacturing conditions.

The KUKA robot itself requires almost no maintenance for 10,000 hours or five years. “As hard as this machine works, there’s hardly any maintenance,” Berroa said.

The waterjet pump costs less than half to operate than the KMT pumps used in other brands of sawjets and can last up to three times longer between rebuilds than Hypertherm pumps.

Not All Robots Are the Same

The Robo SawJet was not Trademark Universal Stone’s first foray into the world of stone fabrication automation. Before investing in the BACA Robo SawJet, the company had actually bought a robot from another manufacturer.

“We decided to purchase a Northwood Robotic SawJet,” Berroa said. “After we had that machine for 9 months, we saw that it couldn’t keep up with our workload, either.”

Berroa quickly learned that not all robotics solutions are created equally. “There were a lot of software and reliability issues with the original robot where we couldn’t keep the machine running,” he said. “The machine would just stop on us without finishing all of the cuts. We then had to pick up a teach pendant, and manually move the robot back to a safe position before re-running the job from the beginning. There was a lot of stuff we had to cut by hand even after running it on the machine.”

“The difference in the performance between the two robots was so significant, the decision to change was a no brainer.”

The Better Choice

As time went on, it became clear that continuing to limp along with that machine was not feasible, Berroa said. “We decided to purchase another sawjet,” he said. “We knew that we couldn’t continue to stick with the first machine. We knew it would be costlier to deal with the issues and struggle to meet our production needs than to go ahead and get the right machine.”

That’s when BACA came into the picture. Berroa was invited to the company’s headquarters in Detroit to see the Robo SawJet in action. He liked what he saw.

“It was just clear that it was the equipment we needed,” he said. “BACA took us to different fabrication shop where we actually saw the machine in action. To watch that machine cut and to see how much they were cutting per day was absolutely crazy. When we saw the machine cut, we literally saw the machine cut an entire slab in 11 minutes. That’s when we knew that it would be much costlier for us to keep the original machine. The difference in the performance between the two robots was so significant, the decision to change was a no brainer.”

Another advantage of the Robot SawJet is its compact footprint. “The robot in the first system was really large. The BACA robot is more compact and lower. You don’t have to have an incredibly high ceiling to accommodate it. When you compare the two machines, you initially think that a big bulky robot looks impressive, and must be better, but it’s actually not the case at all. The bigger robot is much more restrictive and doesn’t perform as well”

Installing and Training

While there were many delays with getting the first robotic system up and running, the shop’s experience with BACA was a completely different story, he said. “With BACA, it was totally different. The Robo SawJet came in around the third week of November 2016. By the fourth week, we were already cutting jobs. We’re talking about a week turnaround. They worked absolutely night and day. It was seamless. It was great. There is no comparison.”

While the Robo SawJet was being installed, BACA Systems flew Trademark Universal Stone staff out to its Detroit headquarters for a week of hands-on training. The training process was truly beneficial, Berroa said. “It was really easy. The program is just so user-friendly.”

The Robo SawJet’s PC-based Easy Ready 2 Use™ software is designed to be simple and accessible. After a short training, workers can step in to run the machine as needed instead of having to depend on one or two experienced operators.

“Their software is so user-friendly, anyone can learn to run the machine in a short time,” Berroa said. “The programming was so much easier than the other system. With the BACA RoboCut software, after three days, our guys were fluent with the software.”

Stellar Customer Service

BACA also offers world-class customer service, Berroa said. “It’s so fast and so prompt that it feels like they are right here with us. I’ve never seen customer service like that. It’s not next day. It’s same day.”

If Trademark Universal Stone encounters any issues with the Robo SawJet, they don’t have to wait for a technician to make a trip out to their facility to inspect it. BACA technicians can remotely log on to the Robo SawJet’s onboard computer to diagnose any problems encountered during its operation.

It’s not just technical issues that BACA will troubleshoot for its customers. Berroa said that during a recent garnet shortage, it looked like it would take weeks for the shop to receive an order of the abrasive garnet sand used for waterjet cutting. In desperation, he gave BACA a call.

“BACA told us to give them five minutes,” he said. “Five minutes later, two pallets of garnet were on the way to us. That’s the kind of customer service we get from them. It’s just great.”

“We felt we needed more robots, when in actuality we just needed the right robot”

Future Plans

If Trademark Universal Stone had any need for another sawjet, Berroa said he’d certainly buy another BACA. “I would in a heartbeat. No question.”

Before buying the Robo SawJet, Berroa said he had been consulting with an architect to lay out the Trademark Universal Stone fabrication facility to accommodate additional sawjets to try to boost production. “We felt we needed more robots, when in actuality we just needed the right robot,” he said.